More than 1.7 million workers are endangered by silica dust each year, including construction workers, miners, roofers, and farmers. Anyone in an industry that uses abrasive blasting, jack hammering, drilling, concrete mixing, block cutting, sawing, or tunneling is exposed to the toxic dust. Each year, silicosis claims 250 lives. The disease is particularly insidious for two reasons: once contracted, it’s incurable. Secondly, it is transmitted in the form of dust, which may seem harmless to untrained or distracted workers.

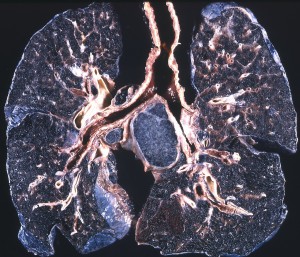

Above is the image of a coal worker’s lungs. Tiny particles of silica and carbon pigment were breathed in but could not be excised from the lungs. The black pigmentation and fibrosis (excess connective tissue) were caused by exposure to this toxic dust. Image via Pulmonary Pathology on Flickr.

The numbers of fatalities due to silicosis are high, and national safety organizations such as OSHA (the Occupational Safety and Health Administration) are championing efforts to curb illnesses and fatalities. OSHA is advocating for reasonable steps that employers and work site managers can take to lessen harmful exposure to silica.

In 2011, OSHA proposed new, lower permissible silica level guidelines. These guidelines would cut acceptable silica exposure limits in half; the original guidelines were decades-old and outdated. Despite the fact that proposed laws like this one are supposed to get a 90-day review, this silica legislation has been stalled in the White House’s budget office for over two years. This unusual delay has a direct cost in terms of lives—according to the government’s own estimates, each year the legislation is stalled, 60 workers are unnecessarily killed by silica.

The cause of this continued delay is hotly debated. But regardless of what red tape is stalling these new standards, the onus is entirely on employers, foremen, and workers themselves to implement safe work practices to reduce these high numbers of dust-exposure deaths. According to the Center for Disease Control (CDC), one of the steps employers can take to prevent silicosis is simply making a commitment to best practices that reduce dust on a work site.

Fortunately, most of these safety practices are just good commonsense ways to settle and eliminate dust. However, workers may underestimate how toxic dust on work sites actually is. That’s where silica warning signage comes in: as a way to reinforce safety training and continually remind workers to be conscientious and vigilant. Since silicosis is an incurable disease, it’s of paramount importance that workers are frequently reminded of ways to keep themselves safe.

These silica signs list best practices that have been gleaned from the CDC and OSHA.

Below are some highlights from Oregon OSHA’s best safety practices for preventing silicosis:

Use respirators, a special type of

personal protective equipment.

When carefully selected, worn,

and used, respirators will protect

workers from inhaling crystalline

silica dust.

Practice good personal hygiene.

Those who work with materials

containing crystalline silica

should wash their hands before

eating, drinking, or smoking.

They should shower, if possible,

and change into clean clothes

before leaving the worksite.

They should never eat, drink, or

use tobacco in abrasive blasting

areas.

Work wet. Use wet drilling or

sawing to control dust. Remove

dust and debris with a wet

vacuum or hose it down, rather

than blowing it around with

compressed air or dry-sweeping it.

Post warning signs. Put up signs

that identify work areas, tasks,

and equipment that may expose

workers to crystalline silica.

The signs should warn workers

about crystalline-silica hazards

and identify required personal

protective equipment.